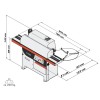

Feed speed: 7 m/min

Panel thickness: min 10 – max 45 mm

Edge thickness in coils: 0,4 ÷ 2 mm

Minimum panel length (Side being processed): 220 mm

Minimum panel width: 110 mm

Teflon coated glue pot

- n.6 heating elements: 4 in glue pot, 1 on the tower and 1 inside motorized glue spreader roller

- The motorised glue spreading roller, with electrical resistance inside,distributes a uniform layer of glue that can be adjusted in thickness on the side of the panel to be processed

Automatic panel feeder with toothed belt

- Feeding speed 7 m/min

- Toothed belt with steel strands inside for stiffness.

- Working table length 1800 mm with Polizene sliding fences

- N. 7 small rollers with adjustable angle position for panel side pushing. Each roller can be quickly taken out for easy cleaning

- Front extensible support up to 60 cm with polizene sliding fence.

Logic functioning controller by PLC

- Thermostatic glue control with automatic standby and temperature

- Complete automation control of the various operating units

- Diagnostics system with messages for machine use and maintenance

- Statistical operating data: total hours of machine use, total and partial metres of edge used

- Brand: CASADEI INDUSTRY

- Product Code: AUTOMATIC EDGEBANDERS E 321

- Very good bonding

- Ready to use in a few minutes

- Easy cleaning and maintenance

- Quick edge changing

- Quick adjustments according to edge used